Workholding solutions play a crucial role in the manufacturing industry, ensuring the secure and efficient clamping of workpieces during machining operations. Hollow power chuck fixtures have emerged as a popular choice, offering numerous advantages over traditional workholding methods. In this article, we will explore the benefits of hollow power chuck fixtures and how they optimize workholding solutions for various industries.

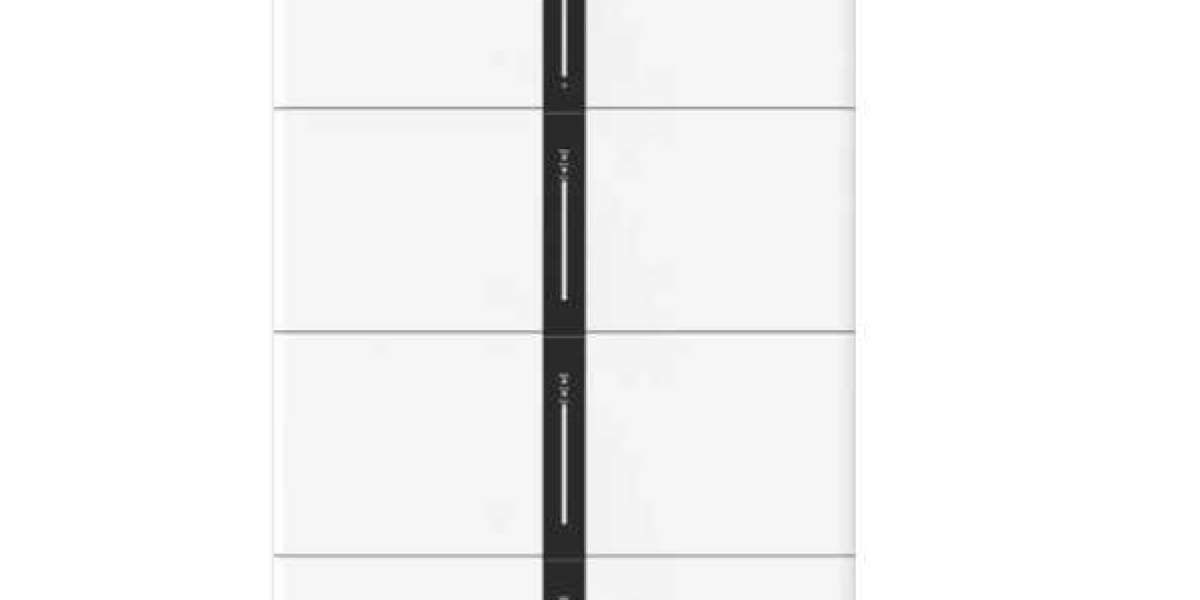

Understanding Hollow Power Chuck Fixtures

Hollow power chuck fixtures are specialized workholding devices that incorporate a hollow interior, allowing for the passage of coolant, lubrication, and other media through the chuck and workpiece. These fixtures typically consist of a chuck body, jaws, and a clamping mechanism. By incorporating a hollow design, these fixtures enable simultaneous machining and coolant delivery, improving productivity and machining efficiency.

Advantages of Hollow Power Chuck Fixtures

1.Enhanced Machining Efficiency:

One of the key advantages of hollow power chuck fixtures is the ability to deliver coolant directly to the cutting zone. This significantly improves machining efficiency by reducing heat and friction, resulting in better surface finishes, extended tool life, and reduced cycle times. The coolant passage through the chuck ensures effective chip evacuation, preventing chip build-up and minimizing the risk of tool damage or workpiece contamination.

2.Improved Workpiece Accessibility:

The hollow interior of power chuck fixtures allows for better workpiece accessibility during machining operations. The absence of coolant pipes or other obstructions within the chuck enables greater tool access and visibility, facilitating more precise and efficient machining. This advantage is particularly beneficial for complex workpieces or applications that require intricate machining operations in hard-to-reach areas.

3.Versatility in Workpiece Size and Shape:

Hollow power chuck fixtures offer versatility in clamping a wide range of workpiece sizes and shapes. The adjustable jaws and clamping mechanism allow for secure and precise gripping, accommodating various workpiece geometries. Whether it's cylindrical, square, or irregularly shaped workpieces, hollow power chuck fixtures provide flexibility and adaptability, reducing the need for multiple workholding setups and increasing overall productivity.

4.Compatibility with Multiple Processes:

Another advantage of hollow power chuck fixtures is their compatibility with multiple machining processes. These fixtures can be used for turning, milling, drilling, and other operations, making them suitable for a wide range of applications. The ability to perform multiple processes without changing the workholding setup saves time, minimizes errors, and improves overall machining efficiency.

5.Reduction in Setup Time:

Hollow power chuck fixtures contribute to a significant reduction in setup time. The quick-change jaw system and easy adjustment mechanisms allow for rapid clamping and release of workpieces. This enables faster setup changes between different jobs, minimizing downtime and maximizing throughput. Additionally, the hollow design eliminates the need for additional coolant delivery systems or external fixtures, further streamlining the setup process.

6.Cost Savings:

The advantages of hollow power chuck fixtures result in tangible cost savings for manufacturers. The improved machining efficiency leads to reduced tool wear, lower scrap rates, and increased productivity. The versatility and compatibility with multiple processes eliminate the need for specialized workholding solutions for different operations, reducing equipment costs and setup time. Additionally, the enhanced workpiece accessibility and chip evacuation minimize the risk of costly errors or damage during machining.

Conclusion

Hollow power chuck fixtures offer numerous advantages over traditional workholding methods, optimizing workholding solutions for various industries. From enhanced machining efficiency and improved workpiece accessibility to versatility in size and shape, these fixtures provide manufacturers with the means to achieve higher productivity, better surface finishes, and cost savings. By incorporating a hollow design, power chuck fixtures enable the delivery of coolant and other media directly to the cutting zone, resulting in improved machining performance and extended tool life. As the manufacturing industry continues to evolve, hollow power chuck fixtures prove to be a valuable asset in optimizing workholding solutions and driving operational excellence.

Hangzhou Chandox Tosun Import Export company focuses on selling mid-to-high-end machine tool accessories such as Taiwan Chandox hydraulic power chucks, hydraulic rotary cylinders, pneumatic chucks, steel body manual chucks, and thin chucks. We also sell Taiwan Otwell precision hydraulic vises, pneumatic vises and mechanical vises, Taiwan Lixin activity centers, Danxing and Parkson CNC turntables, Korean Xinkang special power chucks, large size power chucks and German zero clamps system.

Welcome to contatc us,if you are interested in our products.

Email:Tosam@chandox-tosun.com